At What the Future Food, we’re serious about food. And we’re serious about fun.

Because we believe food isn’t a product: it’s an experience.

Upgrade from handmade. Scale up capacity. Reimagine your business. Reinvent your brand.

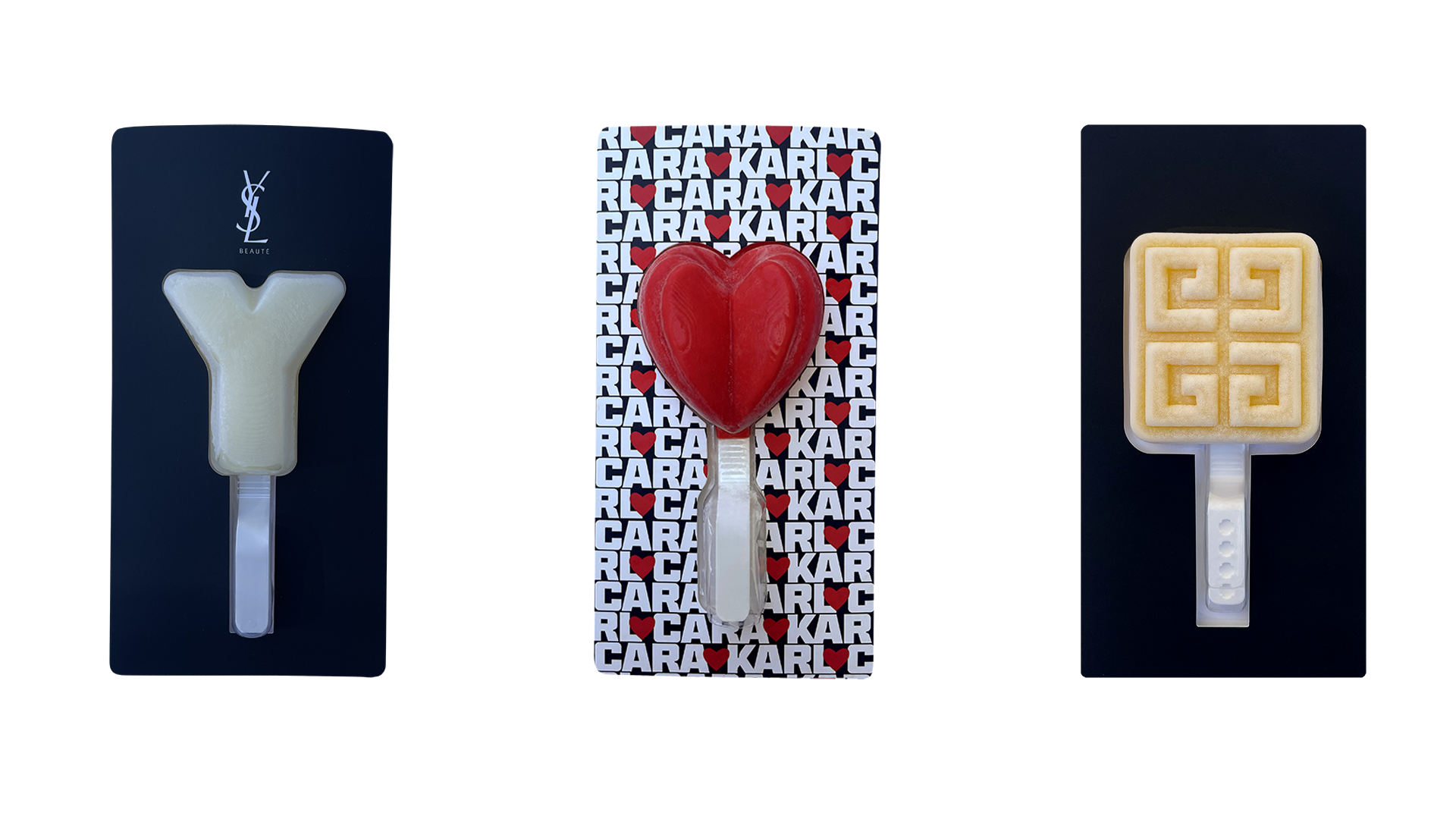

Starting with ice pops

What the Future Food’s breakthrough manufacturing technology enables the production of frozen confections on-demand, from small batches to mass quantities, in any shape, flavor, and volume.

Now you can create custom food products with the immense scale of mass manufacturing and the intricate detail of hand production, at a fraction of the complexity and cost. So that every food experience is delicious, distinctive, and delightful. From the first bite to the last lick. Our technology also enables the production of chocolate on-demand, in almost any shape.

In fact, our tech can process any liquid, paste or gel. What do you want to make? We're ready to bring your ideas to life.

Maximum impact. Minimal complexity. Big on delight. Low on cost.

3DTI is a manufacturing technology that blends the best of 3D printing, thermoforming and injection. 3DTI combines hardware and software to help manufacturers achieve unprecedented flexibility in production. At the greatest possible speed, and the lowest possible cost. For the industries that need it most.

3D printed tooling

Due to the use of 3D printed molds, shapes can be changed quickly on 3DTI production lines. This in combination with on-machine injection enables same day production of multiple products at a lower cost than existing mass production processes.

Thermoforming

Our patented technology transforms standard thermoforming machines into flexible high velocity production lines by utilizing low cost air-cooled 3D printed molds.

After production the molds are shredded, pelletized and utilized to create filament for new molds.

Injection

3DTI has many possibilities in a variety of applications and can process any liquid, paste or gel. The on-machine injection enables same day production of multiple products at a lower cost than existing mass production processes.

3DTI powers local production, simplifying supply chains, reducing risk and enabling manufacturers to meet fast-changing demand.

Our tech utilizes low cost 3D printed molds in place of traditional CNC milled aluminium/steel molds. As a result, Start of production is reduced from months to hours. This enables rapid and cost efficient development of new products and radically reduces time to market.

Start of production is reduced from months to hours.