3DTI is the only technology that can make a multitude of shapes for less than it costs to produce a single shape with any other manufacturing technique.

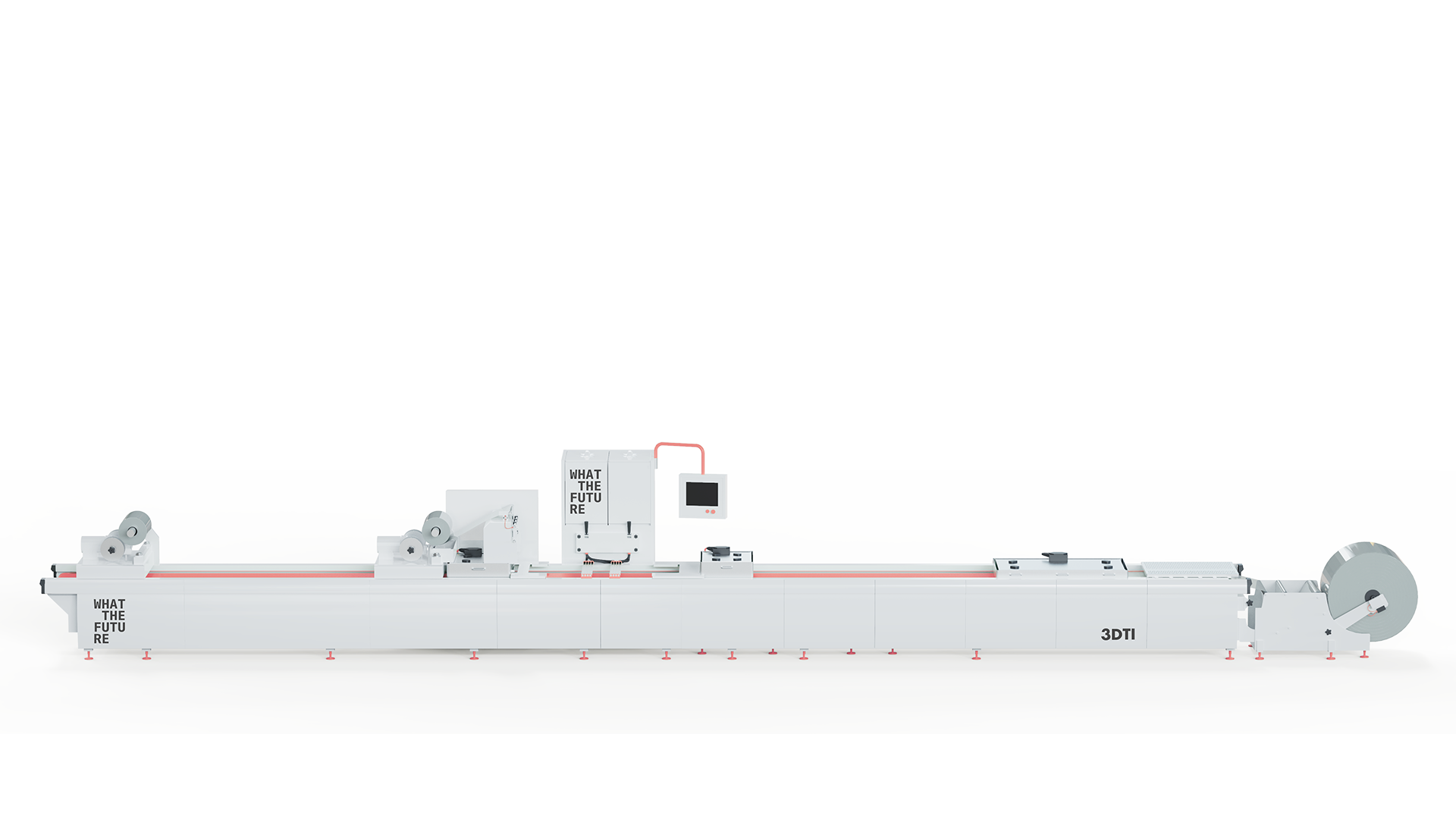

Think of 3DTI as a micro-factory that packs tremendous scalability into a tiny footprint. Configured to your specifications, wherever you need it, wherever your customer is.

Before we make better things, we need to make things better.

With low capital outlay and global technical support, Your 3DTI production line is designed to:

- Create thermoformed cavities in a fraction of a second — in any shape or volume

- Inject any cold pour substance — liquid, paste or gel

- Produce several different types of products—all on the same line

Notice the difference at any production facility:

- Eliminate tooling costs

- Manufacture multiple shapes for less than the cost of one*

- Produce packaged, consumer-ready products on one line

- Ramp up or scale down volume

* compared to existing manufacturing techniques.

See the impact on the bottom line:

- Cut time to market, beating competitors

- Lower cost on short production runs

- Produce high-margin seasonal items

- Open up new business opportunities

By combining and automating existing techniques, 3DTI digitizes, simplifies and streamlines custom food production at any volume. With a footprint that’s 50% smaller* than conventional ice pop facilities, 3DTI merges seamlessly into any production location. To produce ice pops, 3DTI uses:

- Tooling from a bio-based, biodegradable polymer that can be pelletized for 100% circularity

- Packaging from PET that uses 60% recycled content, and is 100% recyclable

- Ice pop sticks from compostable paper compound, a renewable source material

HAVE a production facility? We can transform it.

WANT a production facility? Let us make one for you.